In recent months there appears to have been a reluctance to explore innovations and improvements to the global automotive supply chain. The knock-on effect has been the delay in making decisions on investments through the supply chain.

There are many questions that remain unanswered around Brexit but one thing is certain – the need for the automotive industry to continue to function and plan for the future.

At the last Automotive Logistics UK Summit, the need to increase productivity and connectivity through the supply chain was a hot topic. This points to the need to be open to looking at methods of improving the supply chain and addressing the issues that face the industry today and tomorrow.

The automotive industry will be facing the same challenges today around cost savings, improving efficiencies and reducing emissions, as they will after Brexit. This is regardless of the trade agreements that will be put in place.

The automotive industry cannot afford to sit around and wait to see what happens with Brexit. Customers will still want vehicles therefore importing and exporting of components and finished vehicles will have to carry on.

The aim is to remain competitive, one way to address this is by reducing costs, an avenue that you should explore is implementing intelligent returnable packaging.

The need to transport larger quantities of components in shorter timeframes requires increased capacity and the need to improve the use of space both in transportation and storage.

We have designed a 52kg plastic returnable bin with a 900kg weight capacity allowing you to ship Power train, body white and trim parts using one bin. The EuroBin can be stacked 10 high when folded allowing you to transport 260 bins per trailer providing a significant cost down in comparison to other bins on the market.

When erected the EuroBin can be stacked 3 high resulting in 78 bins per mega trailer, this results in a large cost saving for transporting goods across the continent.

As well as the capacity benefits, the EuroBin aids productivity in during manufacturing as all four sides can be dropped down when in use at line side. This removes the need to walk around the bin unlike current bins in use in the market.

It is time that the automotive supply chain begins to look at ways of improving processes today rather than worrying about Brexit – if we sit and wait until then it will be too late to play catch up.

More News

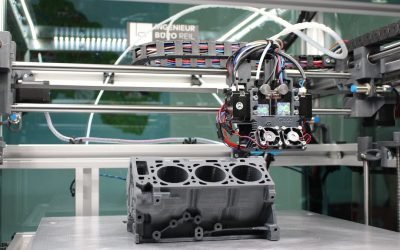

Fascinating to Frightening prospect of the Automotive Industry adopting 3D Printing

3D printing is set to disrupt the automotive manufacturing and supply chain operations, with the technology speeding up innovation and rendering the supply chain redundant. During a conference recently, I hosted a discussion on the impact of the introduction of 3D...

Macro Plastics partner with Tri-Wall to transform the Automotive supply chain

Macro Plastics have been working closely with Tri-Wall to integrate expendable cardboard packaging into our plastic foldable returnable bins such as the ISOBin and the innovative EuroBin 1210. Our global partnership focuses on developing packaging solutions that...

Macro Plastics launch the first 100% recyclable Plastic Folding Pallet bin for the automotive supply chain

The EuroBin 1210 is made from virgin polypropylene to ensure high quality performance throughout its life cycle and is the preferred material of the automotive packaging industry. The EuroBin is 100% recyclable with only polymer type for all plastic components unlike...