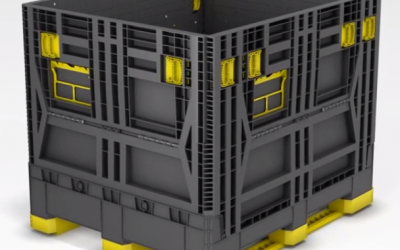

Macro Plastics have been working closely with Tri-Wall to integrate expendable cardboard packaging into our plastic foldable returnable bins such as the ISOBin and the innovative EuroBin 1210.

Our global partnership focuses on developing packaging solutions that reduce costs, emissions and damages for our OEM and tier supplier clients in the global automotive industry.

We are joint sponsors with Tri-Wall of the Automotive Logistics Europe Conference 2018 in Bonn 13th– 14th June.

Over the course of the conference, we will be demonstrating how we have integrated Tri-Wall’s expendable packaging innovations into the Macro Plastic returnable bins.

Tri-Wall have worked on a series of projects with us to design packaging to transport a wide variety of components

While Tri-Wall’s specialty is to provide well-engineered, bespoke packaging solutions for its customers, standardised products are an integral part of its product offering. Their core competence is finding unique and innovative designs for packaging solutions to optimize pack density and maximise container volumes. This in turn generates cost savings for our customers and the emissions omitted during transportation.

Macro Plastics and Tri-Wall’s aims are closely aligned which provides an ideal platform to combine our expertise to deliver the best possible packaging and supply chain solutions to our clients.

At Macro Plastics, we strive to improve the efficiency of our clients’ supply chain through optimising space at each stage of the supply chain from storage through to transit. Through Tri-Wall’s expertise, we are able to optimise the space in our plastic returnable bins to ensure that the maximum amount of product can be stored without comprising the safety and quality of the contents.

Maximising the space in the bins themselves and the space taken up by the bins when stacked and in transit reduces the clients costs whilst reducing their carbon footprint. The environmental impact of the automotive is high on the agenda and using plastic returnable bins removes the need to use large quantities of expendable packaging and significantly reduce the number of trucks required to transport components.

We look forward to meeting delegates at the Automotive Logistics Conference in June who would like to know more about how our partnership can help them improve their supply chain and logistics operation.

More News

Now There is No reason to say No to Returnable Packaging

Changing the Automotive industries perception of Recycled Returnable Packaging There has been a longstanding question from automotive manufacturers about what happens to returnable packaging at the model end-of-life stage? There is also the perception that all...